Our installation example of IH systems

We have designed and developed IH systems that utilize IH (Induction Heating), and we have delivered many IH systems for the heating processes of major manufacturers and for experiments at research institutes.

The built-in IH power supply (invertor) with advanced solid state technology provides easy operability and controllability in a compact configuration.

The following are sample of our IH systems.

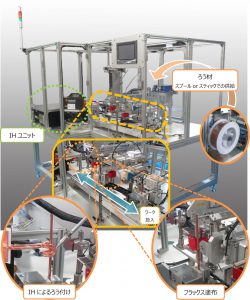

IH automatic brazing system

Labor-saving brazing contributes to decarbonization

IH automatic brazing machine that greatly reduces the burden of brazing processing.

By utilizing IH, it provides easy operability and controllability in a compact configuration.

IH (induction heating) solves various brazing problems such as limited workers and poor work environment due to heat.

Even aluminum with low electrical resistance can be adapted with quick power control.

Soldering system for solar cells

Automates soldering with point heating, line heating, and a variety of heads.

Hardening system

By uniformly heating the inner hole of the shrink-fitting target, the size of the hole can be widened and the shaft can be easily inserted.

Quenching system

Accurately concentrates heat to the right depth from the surface and gives you the control you need.

Local annealing system for jet engines

Accurate temperature cycles can be obtained through control in combination with a thermometer or temperature controller.

Levitation melting system

Proper control of power can levitate molten material.

No contamination by impurities and no mechanical interference.

Glass fusion system

Provides the control and precision needed to heat to extremely small areas.

150 kW heat exchanger

We also manufacture heat exchangers utilizing our thermal control technology.