How to Select an IH Power Supply

The core of IH (Induction Heating) system is the IH power supply (generator).

The IH power supply generates a magnetic field around the work piece to be heated by sending an alternating current through the heating coil.

The output and frequency of the power supply vary depending on the heating range, heating temperature, and other heating processes required for the workpiece.

Output

The output of power supply determines the speed at which the heated object (work piece) rises in temperature.

For example, if a brazing process is done at 3 kW, increasing the power to 5 kW will complete the process faster.

However, increasing the output of power supply will increase the size and weight of the power supply, and will also require larger electrical facilities and cooling water capacity.

Frequency

There is a correlation between the frequency of the alternating current and the depth of heat penetrating the heated material (work piece).

Lower frequencies from 5 kHz to 30 kHz are suitable for thicker materials that require heating deeper into the material, while higher frequencies from 100 kHz to 400 kHz are suitable for smaller parts and shallow heating.

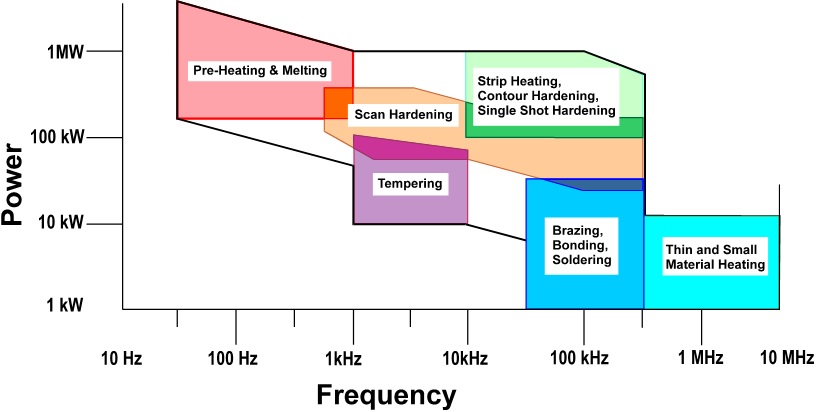

Typical IH Applications

Spectrum of products

Ambrell IH power supplies are available in two series: the compact EASYHEAT series and the mid-power or higher EKOHEAT series. You can choose the one that best fits your needs.

If you are not sure which model to choose, please let us know the heating requirements of the work piece to be heated, and we will guide you to the appropriate model.

Please feel free to contact us.

EASYHEAT series

For small part manufacturing processes that require clean, quick heating!

EKOHEAT series

From middle power to high power for reproducible and reliable heating!