IH (Induction heating) is a non-contact heating method for heating conductive materials (mainly metals).

IH, which does not use a flame and is easy to control, is attracting attention as a waste-free heating process that is friendly to the global environment and the work environment, reducing carbon dioxide (CO2) and environmental impact.

It is also a familiar technology used in induction cooktops in homes.

Principles of IH

The principle is based on the phenomenon of electromagnetic induction discovered by the British scientist Michael Faraday in 1831.

This phenomenon generates heat (Joule heat) in a conductor when an induced current flows through it.

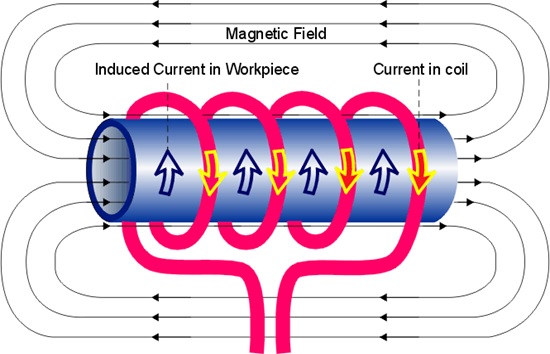

The alternating current flowing in the heating coil creates a magnetic field that induces an electric current in the metal (to be heated) itself.

Eddy currents (currents in the opposite direction of the coil current) are generated in the metal. This eddy current and the electrical resistance of the metal generate Joule heat, causing the metal to rapidly self-heat.

Plastics and non-conductive materials can also be heated by susceptor heating using a metal susceptor.

Applications

IH is widely used in various industries for brazing, quenching, and other applications.

We introduce application examples based on our extensive experience and achievements by industry and by use.

We have prepared application notes and video clips for each case study, so please refer to them for your desired heating process.

Configuration of IH system

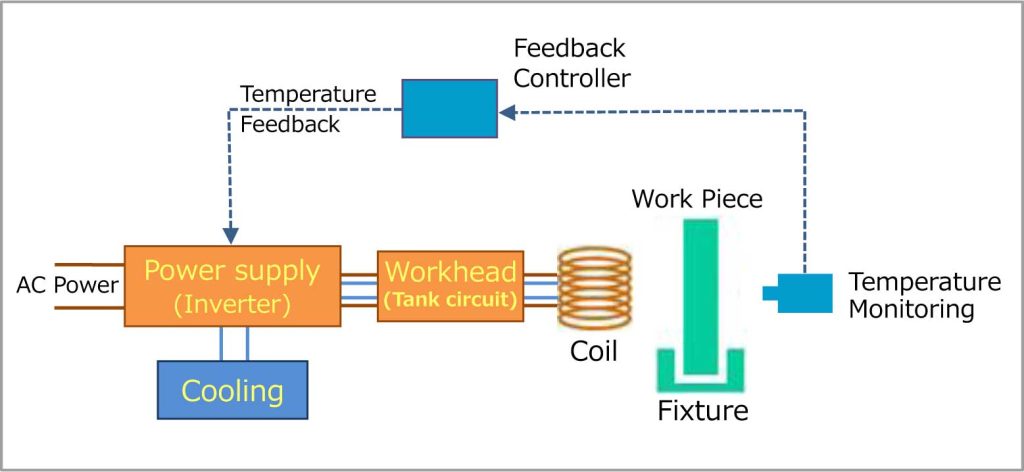

The basic components of an IH system are the induction heating power supply, the coil for heating, and the work piece to be heated.

An IH power supply applies an alternating current to a coil and generates a magnetic field.

When the material is placed in the coil, the magnetic field generates eddy currents in the material, producing clean, precise, controllable heating only in the area to be heated, without physical contact between the coil and the material.

The temperature can be monitored with a radiation thermometer or thermocouple, and the output of the power supply can be controlled through a temperature controller.