Reproducible and reliable heating

EKOHEAT technology improves return on investment by reducing your energy usage compared to gas-fired and resistive heating techniques. Flameless, non-contact induction heating minimizes energy waste by focusing energy only on the part and zone to be heated. With very efficient power conversion and a power factor greater than 0.9, utility demand charges are reduced, lowering monthly energy bills.

EKOHEAT VPA systems are designed on a host/client principle so you can add additional power should your process require it in the future.

EKOHEAT now has a compact model!

The new compact EKOHEAT has all the functions of the current EKOHEAT.

Volume: 64% reduction, Footprint: 53% reduction

Applications

The EKOHEAT series is mainly used for the following applications.

- Brazing

- Gluing

- Soldering

- Melting

- Adhesive curing

- Heating

- Wire heating

Features

1. Automatic Frequency Tuning

The frequency of the power supply is automatically adjusted to the resonance frequency, eliminating the need for troublesome frequency adjustment.

Even if the resonant frequency changes, it is automatically followed within the entire output frequency band, so energy can always be supplied to the workpiece (to be heated) at maximum efficiency.

2. Constant output control

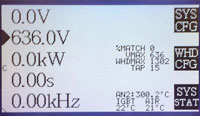

Constant control by RF output voltage or RF output power (switchable) is possible.

The output power is controlled by the actual RF power applied at the workhead. Internal losses in the power supply are not a concern.

3. Record/Playback Functions

The ability to record and play back application data makes quality control easier.

All parameters such as RF voltage, frequency, etc. are recorded at 200 ms intervals. Records are stored on an SD card for up to 35 days.

Easily operated from the home screen, playback is possible at rates from 1/5 to 5 times the actual time. Data can be imported into Excel for analysis.

4. Auto Scan Function

This function automatically sets the starting frequency and suggests appropriate taps. It can be operated with more efficient and appropriate settings.

With a simple operation of a button on the home screen, it scans applications and automatically sets the start frequency according to the application to be heated. It also suggests appropriate taps for the application.

5. Soft start circuit

To prevent inrush current at power supply startup, a soft-start circuit function for 5 seconds after startup minimizes inrush current

Compliant standards, etc.

CE Mark compliant

All models conform to the CE mark, so you can rest assured that they can be deployed in overseas factories.

RoHS compliant

Complies with RoHS and does not use hazardous substances.

ISO 9001:2008 certified

All Ambrell systems are manufactured in ISO 9001:2008 certified U.S. facilities.

Easy-to-use

Easy operation with touch panel

Setting data, parameter changes, etc. can be easily made from the front touch display.

In addition to English, the display is available in Italian, Spanish, German, and French. This makes it easy to deploy the system in overseas factories.

Compatible with Ethernet

Industrial protocols such as EthernetIP, Modbus/TCP, and PROFINET are fully supported.

It also has an RS485 serial port for easy remote operation.

Two remote inputs

The use of a secondary remote input increases versatility.

Measure, display, record, and replay process variables such as temperature, along with associated parameters.

EKOHEAT Models

You can choose from our extensive lineup according to the output you need.

If you are not sure which model is best for you, please feel free to contact us.