For aluminum pipes, automotive parts, etc.

Difficulties in Thermal Processing of Aluminum

Since aluminum is a light and strong material, it is used for various parts such as piping parts and automobile parts.

However, it has been said that thermal processing is difficult due to its characteristics.

High thermal conductivity

Its thermal conductivity is approximately three times that of steel.

The advantage of aluminum is that it conducts heat easily and is often used as a heat-dissipating material, but it can also be a disadvantage when heat processing.

Even if you want to heat only the desired part, the heat will be transferred to other places and distortion will occur.

Low melting temperature

The melting point of aluminum is 660℃.

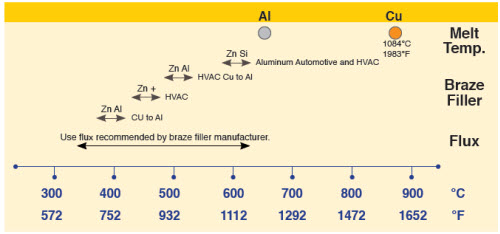

Since its melting point is close to that of silver and copper solder, which are commonly used in brazing, brazing aluminum has required advanced techniques by skilled workers.

Aluminum Brazing by IH

Induction heating with excellent temperature control, and the use of braze fillers (made by Daiichi Kigenso Kagaku Kogyo) for aluminum brazing enables efficient brazing of aluminum.

Video: Aluminum brazing with an IH automatic brazing system

You can see the process of brazing aluminum pipes with an IH automatic brazing system.

Induction brazing offers numerous benefits

- Throughput: Induction generates heat only to the portion of the part needed for brazing

- Better efficiency

- Better quality with less part distortion

- Repeatability: After the coil and heating process are defined, you can count on a precise, consistent quality braze every time

- Easy Integration into a lean manufacturing process

- Safety: No open flame or hot furnace

- Small Footprint: Frees up valuable factory floor space

Video of aluminum brazing application examples

Aluminum Brazing Materials Temperature Spectrum