IH ideal for heating furnaces

Induction furnaces are mainly used for the following applications;

- Hardening

- Brazing

- Soldering

- Melting

- Drying

Heating using IH reliable, reproducible, and energy-efficient heating in a short period of time.

In addition, time and temperature can be precisely controlled.

Therefore, heating is instantaneous, without waiting time, only when it is needed, reducing wasted energy costs.

Compared to other types of heating furnaces, Our induction furnaces are extremely compact, generate no noise, and produce no exhaust or wasted heat.

In addition, the fact that no flame is used suppresses the temperature rise in the workplace, making it an environmentally friendly product that greatly contributes to improving the work environment.

Benefit of induction furnaces

- Compact size

- Simple ON/OFF operation

- Fast start-up and shutdown

- Accurate heating control

- Reduced energy costs

Application

Induction furnaces can be used for various applications such as hardening, brazing, soldering, melting, and drying, and are available in various sizes depending on the object or process to be heated. For curing after bonding or drying after painting, simply insert the object to be heated into the furnace and turn on the switch.

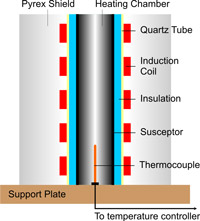

Heating patterns and temperatures can be set according to process specifications. Even if the part to be brazed or soldered has an unusual shape, the cylindrical metal susceptor (see left) ensures uniform heating of the entire part.

The process is also reproducible and stable, even for parts made of non-conductive materials such as through-ceramic terminals or PC boards. Power, time, and temperature can be freely controlled by operating the induction heating power supply.

Melting metals such as silicon, steel, and titanium requires a somewhat different approach.

The material to be melted is placed directly on a susceptor made of conductive material that is heated by an induction heating coil.

Custom specifications

Starting with a compact 1Kw mini furnace, we also support atmospheric and vacuum specifications from 30W to 120Kw.

We also manufacture a gas circulation system to reduce cooling time.