Handle Hermetic Seals Cleanly

In the food and medical industries, where airtightness is required between the cap and container, IH provides clean, non-contact heating.

Video: IH Cap Sealing application examples

Advantages of IH

High speed processing, such as sealing aluminum caps on plastic containers, is possible.

- Reliable sealing

- Easy integration into production lines

- Fast processing speed

Cap Sealing application examples

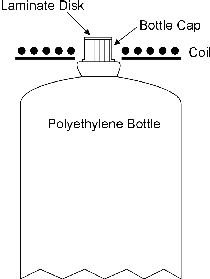

The cap-to-container seal consists of a laminated disc composed of a wax layer, an aluminum layer, and a polyethylene (PE) layer (shown left). The aluminum layer is heated to 125-150°C in an electromagnetic field generated by an induction coil to act as a susceptor. It then heats the wax and PE layer sufficiently to produce an airtight seal between the cap and the container. Heating times are as low as 100 milliseconds to support fast automated processes.

RF power supplies suitable for cap sealing have a power range of 1 to 20 kW, depending on application.