Automated soldering

The IH high speed soldering module (Alonics original system) improves the soldering process in solar cell manufacturing.

Features of IH high-speed soldering module

Faster Process Time

- Soldering bus bar and the interconnector: 0.1-0.3 second per point

- Soldering of cell electrodes: 1-2 second per point

High Controllability

- Start-up time of 5ms, Compact induction heating system with high-speed automatic frequency tuning

- Programming output and the heating time, Save multiple recipes

- Acquisition of process data by RS485 control (optional)

- Monitoring and controlling the temperature of the heating (optional)

Clean Heating

- Direct non-contact heating by Induction Heating

- Improve the quality of soldering

Saving Energy

- Power consumption is only heating time, No need for constant output ON

power supply EASYHEAT

Power supply EASYHEAT is the product of standard specifications. Short delivery time without any worry of maintenance, can be adapted to the production line with confidence.

Flexible adaptability

Weight of the head is about 2.6kg.

The work head can be located up to 4m from the power supply.

It is also possible to adapt to automated robotic machine.

Versatile head: point heating type

Soldering bus bar and the interconnector. Soldering bus bar and the terminal.

- Soldering bus bar and the interconnector:0.1-0.3 second per point

- Welding with flux-less

- A variety of Holding can be selected (Plane pin, Fixing pin, Spring-loaded slide pin)

- Soldering up to 3-4 point simultaneously by one heating module

- Corresponds to the specification depending on the application (Head style, Length of pin, etc…)

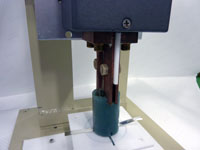

Fixed pin type

Spring-loaded slide pin type

3 locations simultaneously (each spring-loaded slide pin type)

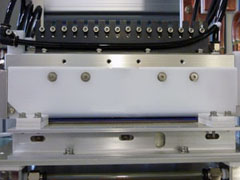

Versatile head: line-heated type

- Soldering of cell electrodes:1-2 second per point

- Soldering multiple line at once using multiple units

- Available in various specifications

- Specified the length of heating

- The length of heating: variable/non-variable

- Regulatory mechanism of the temperature gradient in the longitudinal direction: available/no available

- Air purging: available/no available

- Holding pin: Number, Pitch, Length of the protruding, Strength of the spring

- Over the holding pin assembly (Allows you to exchange after)

- Installation of small radiation thermometer

* Some specifications cannot be duplicated depending on the size of the pushpins.

Various specifications are available to meet your application needs

Versatile head: Dedicated back contact type

The photo is a sample. Actual specifications are subject to change. Please contact us for details.

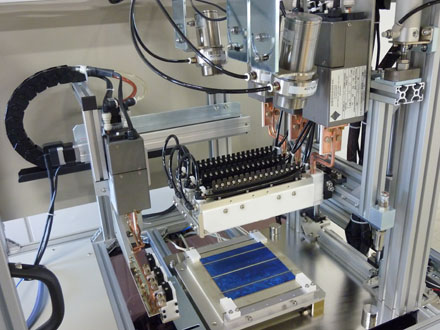

IH Soldering system

IH automatic soldering system by your specifications

- With a single IH power supply, the point heating head can solder 1 to 3 points simultaneously, and the line heating head can solder 1 line simultaneously. Multiple units can be mounted.

- Soldering of multiple lines of cells simultaneously by using 2 to 3 line heating heads: 1 to 2 sec./sheet.

- Even with a single line heating head, multiple lines can be easily soldered at low cost by adding a positioning stage: 1 to 2 sec./location.

- A precision hot plate is used for cell soldering preheating to prevent poor adhesion due to differences in temperature gradients.

- The output can be programmed for time and current. Four 5-step programs can be stored to control temperature rise, fall curve, and temperature hold.

- By installing a radiation thermometer, the temperature of the cell surface can be measured, and the output of the IH power supply can be controlled at high speed through the temperature controller.

- The IH power supply can acquire process data, change settings, and transmit heating profiles via RS485.

- Preheating temperature, heating output, heating time, heating gap, etc. can each be fine-tuned for various applications.

Product Examples

The following is just an example. We will design and manufacture equipment according to your desired specifications. Of course, it can be applied to soldering other than solar cells. Please feel free to contact us.

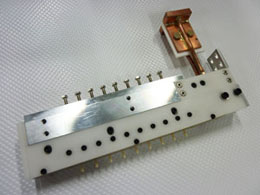

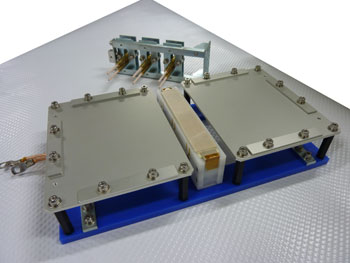

3-line heating head + 3-point heating head combination type

- 4 IH power supply units + cooling unit

- 3-line heating head automatic vertical drive

- 3-point heating head 2-axis automatic drive

- Precision hot plate

- Temperature measurement and control by 3 radiation thermometers + 3 temperature regulators

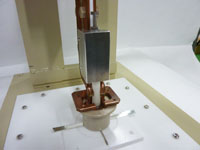

1-point heating head

- 1 IH power supply + cooling unit

- Manual vertical drive of heating head