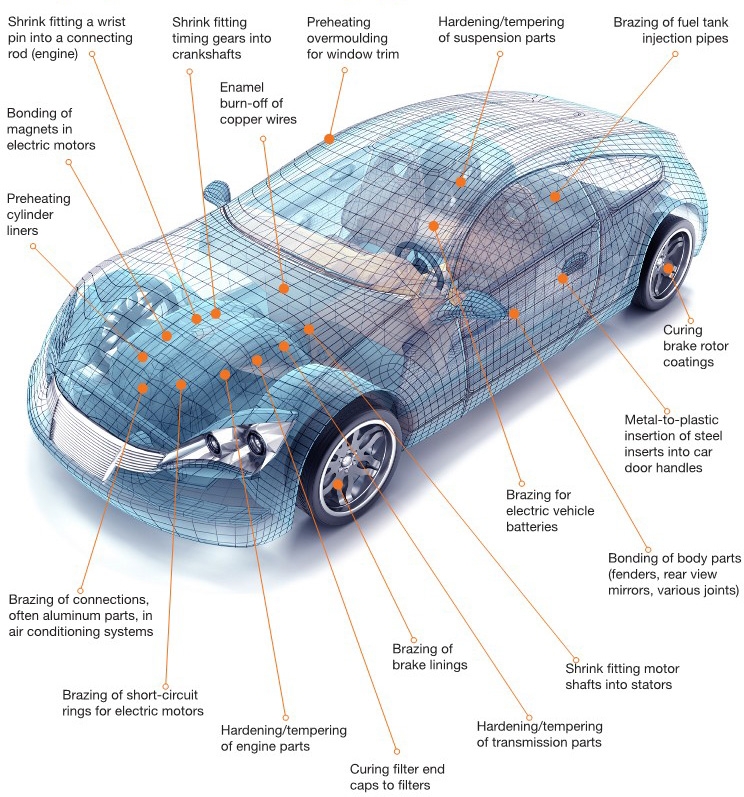

Thermal processing for manufacturing various auto parts

IH is used for thermal processing in the manufacture of various automotive parts such as bodies, engines, electrical circuits, steering, fuel systems and exhaust systems.

Our IH systems offer fast, repeatable, reliable and precise heating for your parts and automation systems.

Large parts such as camshaft gears can be heated more effectively by using a lower frequency, while smaller parts such as flexible electronic circuits can be heated more effectively by using a higher frequency.

Benefits of IH and its contribution to achieving the SDGs

IH systems based on advanced solid-state technology have many advantages such as rapid heating without flames, etc. It solves problems in the manufacturing of automobiles and automotive parts, and contributes to a decarbonized society (Carbon neutral) and the achievement of the SDGs.

Reduces greenhouse gas (CO2) emissions and improves energy efficiency

Reduces fossil fuel combustion

Reduces temperature rise in the manufacturing site and improves air conditioning efficiency

Reduces the risk of worker accidents (burns) and promotes a safe and secure working environment

Sampling of Automotive Applications

In many heat-using processes such as brazing, soldering, quenching, and shrink fitting, induction heating with its superior reliability and reproducibility provides highly accurate manufacturing processes with no variation.

In addition, the compact configuration of IH system can be easily integrated into production lines.

Example of applied heating [temperature/time]

| Work | Parts | Temperature/Time |

|---|---|---|

| Atmospheric Brazing | Hydraulic Hose Assemblies | 1204°C / 7sec |

| Bonding | Trim Vinyl Covering | 260°C / 7sec |

| Bonding | Rubber Gaskets to a Steel Gas Intake Manifold | 160°C / 8sec |

| Hardening | Armature Shaft | 927°C / 2.5sec |

| Brazing | Oil Suction Assembly with Copper Ring | 1010°C / 15sec |

| Curing Adhesive | Aluminum Auto Trim | 260°C / 10sec |

| Curing Adhesive | Steel Motor Shaft | 143°C / 30sec |

| Bonding | Rear View Mirror Brackets to Windshield Glass | 149°C / 5sec |

| Hardening | Seatbelt Retraction Gear | 927°C / 2sec |

| Heating (Stress Testing) | Engine Valve Head | Long-term endurance test at 482°C |

| Pre-heating (Welding) | Truck Axle Seam | 149°C / >15sec |

| Inserting | Steel Studs into a Plastic Tail Light | 232°C / 15sec |

| Shrink fitting | Camshaft Gear | 260°C / 4min |

| Shrink fitting | Steel liner into a cylinder for a mud pump liner | 191°C / 60sec |

| Soldering | Radio Antenna | 316°C / 2sec |

| Soldering | Stainless steel connector to wire harness | 84°C / 6.5sec |